Proud Partners of

CPI Brazil

Products of CPI

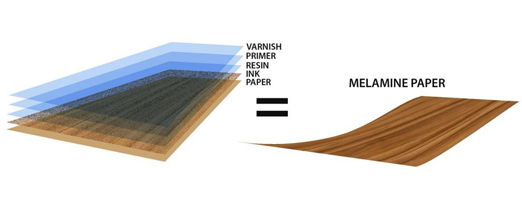

Printed ink is added to the paper. The ink is water based so that the absorption is good. Now the melamine resin is applied. The surface of the paper is smoothen for good absorption. After that primer is applied for the best results. In the end varnishing is done on top for a shiny and a protected melamine surface. Like this a melamine paper is ready to be used

Melamine Coating Foils

Flexforma

Absolute flexibility even in the largest thicknesses

Flexforma

Absolute flexibility even in the largest thicknesses

Finishfoil

Low cost solution for coating MDF profiles for furniture

Finishfoil

Low cost solution for coating MDF profiles for furniture

Primerfoil (FP)

The smartest way to prepare the wooden substrate for painting

Primerfoil (FP)

The smartest way to prepare the wooden substrate for painting

Flexilam

Unique combination of strength and flexibility

Flexilam

Unique combination of strength and flexibility

Flexwalk

High abrasion resistance with flexibility for coating floor profiles

Flexwalk

High abrasion resistance with flexibility for coating floor profiles

Balancingfoil

Tailored balance

Balancingfoil

Tailored balance

Preglued

Perfect finish of the furniture even with manual application

Preglued

Perfect finish of the furniture even with manual application

Melamine EdgeBanding

Solution for different substrates and types of edges

Melamine EdgeBanding

Solution for different substrates and types of edges

Markets

Furniture Industry

Melamine edge products

All application types

- Straight edges

- SOFT edges

- Non visible edges

- Painted edges

PreGlued edge products

- Manual application, usually in woodworking

FlexForma and Flexilam products

- Production of profiles, doors and other components

Balance Foil products

- Counterbalance in the process of laminating panels with wood veneers, FinishFoil, high pressure laminate and other materials

Doors Industry

FlexForma and Flexilam products

- Door surface coating with melamine naturalness and resistance

- Covering profiles with perfect match with the doors

Melamine and T-shape edges products

- Door edge finishing with the sophisticated T-shape system (FALZ)

PVC edges products

- Door edge finish for greater impact resistance

Laminated Flooring Industry

Flexiform products

- Skirting board with perfect match with the floor

FlexWalk products

- Coating of accessories requiring high traffic resistance (T profile, etc.)

Lining and Wall Covering Industry

FlexForma and Flexilam products

- Flat lamination on panels for lining and partitions

- Covering of PVC, WPC, MDF profiles for ceilings and wainscoting

About CPI Brazil

#2nd world ranking in melamine edges

We were one of the very first companies to produce melamine edges in the world, we master the best technology and our product lines cover the widest range of applications.

Absolute leader in Latin America

We are the leading company in Latin America in melamine edges and coatings.

Half a billion meters per year

We are grand in what we do and in our business, size matters a lot. We produce more than half a billion meters of edge tape per year – and we continue to grow above and beyond.20,000m² of factory

To support this entire operation, we are installed in two separate plants: one for the production of melamine edge and coating tape and another for the production of Tegus PVC Tapes.

4 continents from the most demanding markets to the most competitive markets

We operate on a global scale, but more than that, we are able to serve from the most technically demanding markets, such as the USA and Europe, to the most competitive, such as India and China. This says a lot about our determination and our potential to adapt to different environments and cultures.

Expertise in the key areas makes us so strong: Printing | Impregnation | Extrusion | Surface treatment | Adhesives

These are the areas where our technical knowledge and experience accumulated over 40 years make a difference. The combination of mastery of these competencies allows us to develop, produce and deliver world class products with agility and security for the different applications of our customers.Want to know more?